For the plastic crates, which is widely used for goods turnover and shipping, it has standard size for containing capacity and convenient stacking during shipping. The popular size include 600*400mm, 500*300mm, 400*300mm with different height. The length and width could fit well with pallet at the bottom. With the well designed crates, we could ship the goods fast and safety.

|

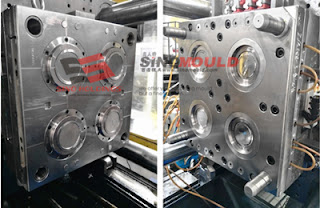

| Popular crate Mould maker China |

For the common vegetable crate, we make more than 100sets crate moulds annually, with P20 steel material and hot runner mould.We could control the crate weight within 1% tolerance according to customer requirement with high precision engraving tooling. There are more than 20 lines separate cooling runner according to the crate shape, with optimized cooling runner, the crate mould running high efficiency with high speed injection molding machine.

Sino Holdings Group is a professional manufacturer for plastic crate production line service, we could supply crate molding equipment with technology support. Welcome to contact us for more detail. Thanks.

Whatsapp: 008615257606120

Email: market1@dakumar.com