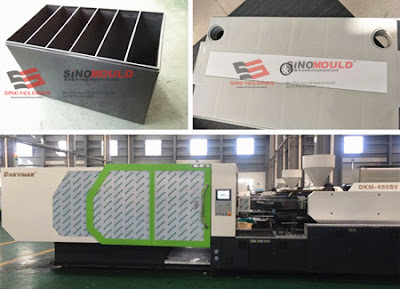

Sino Mould company is the famous China beach chair

mold maker, we can offer customers good quality beach chair mold, armless chair

molds, stadium chair molds, baby use chair molds, Rattan chair molds and so on. We make more than 80sets of plastic chair mould annually. Our market from South America to Africa,located for more than 100countries.

We can offer you solution from product design to the mould shipment, also we have the special engineer to follow the

moulds, we will update the mould process to customers every ten days. The QC department control the mould quality from mould start until mould shipment.

For the beach chair molds the mold material we

usually use the P20, 718H, DIN1.2738 and so on, for the hot runner we have the

Anole hot runner, according to customer special requipements we are OK to use other brands, like the HASCO, YUDO and

other brands hot runner. We have the beach chair design for one piece type, foldable type, with normal size and large one.

As a group company, Sino Holdings Group manufacture for plastic chair moulds and chair injection molding machine, we are factory for injection molding equipment. And we could support you convenient service with best price.

So if you have any new project about the

beach chair molds and other type chair moulds please feel free to contact me, I will offer you all the

solution for the production.

Post by Miss Celina

Email: market1@dakumar.com

Whatsapp: 008615257606120

Post by Miss Celina

Email: market1@dakumar.com

Whatsapp: 008615257606120