Sino Holdings Group company China is a

professional supplier for automotive

parts molding solution, our product range include various automotive parts

mould, like bumper mould, inner trim parts mould, grill mould, lamping system

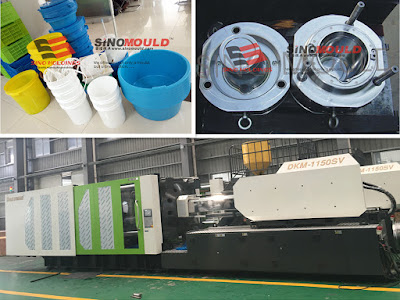

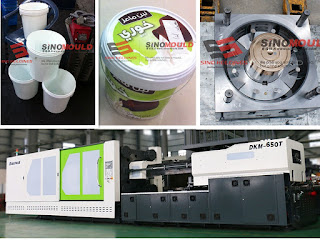

mould, cooling system mould, etc; and plastic injection molding machines size

from DKM50T to DKM4000Ton special designed for automotive parts molding. We

could offer automotive cooling system

production line service.

|

| Automotive injection molding machine |

For the automotive cooling system, there

include the detail parts as water tank, water pump, Radiators, fans,

temperature section, tables and water temperature switches. For the water tank,

there have two types molding ways, one is injection with two parts, the other

is extrusion blowing; The water pump is made by die casting. We could make all

the plastic cooling system parts by injection molding solution, like water tank

molding line, fan molding line, temperature section molding line and so on.

For the automotive cooling fan mould, we

designed with reasonable mould structure, use H13, S136 or other good steel

material for the mould to get long time running and good cooling effect. It is

very important to make sure the cooling fan mould demolding smoothly. The injection

molding machine would be specially designed according to the cooling fan mould.

With our whole line molding solution, we could supply fully-automotive cooling

system production line turnkey project.

Sino company have more than 20years automotive parts molding solution, we

make high quality automotive parts moulds, automotive plastic injection molding

machines, additional machines like chiller, autoloader, air dryer and so on,

part collection robot designed according to the automotive parts shape, size

and plastic raw material. If you are interested in investing new production

line for the automotive part molding, welcome to Sino. Thanks.

Post by Miss Celina

Email: sinoauto@live.cn

Skype: sinomould.dakumar7

Whatsapp: 008615257606120