If you feel thirsty, you will

take a bottle of water to drink. When you unscrew the water bottle cap, have you noticed the lid size and design? Are you

interested in how to produce the bottle

lid?

For the plastic water cap, there are two molding ways,

one is by the injection molding, and another one is by the compression molding.

Both two molding solutions for the plastic lid production are high efficiency

to manufacture qualified water caps.

Compared to the compression molding, plastic injection molding way could get

more stable quality caps with multi-design solution.

Sino Holdings Group is Chinese

famous plastic injection mold and plastic injection moulding machine manufacturer, we could make plastic water cap

mould and

high speed cap injection molding machines. With combined technology, we are

experienced in supplying plastic cap production line include water cap mould, cap injection machine,

relevant auxiliary equipment, installation and training service.

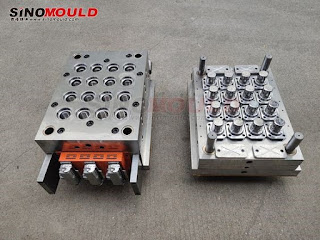

Sino has rich experience for multi-cavity

water lid mould for 4 cavities, 8

cavities, 16 cavities, 24 cavities, 32 cavities, 48 cavities, 72 cavities …We

will recommend suitable cavity for customer based on hourly capacity demands. Our

cap mould use stainless steel S136

made by Stavax in Sweden with interlock type insert design for core and cavity.

With optimized cooling system, we could get the cycle time within 12s for water cap mould with slides.

For multi-cavity cap mould, we could designed the mould

without sliders, we will supply cap slitting machine to get the thief ring

cutting.