|

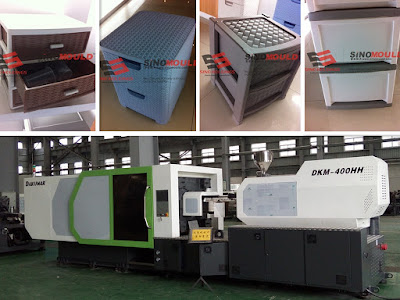

| Milk crate mould China |

Usually we use 718H or other good steel material for the mould core and cavity, with hydraulic cylinder at the cavity side for the sliders moving. The mould could run within 28s with all the cooling runner separate connecting. According to customer requirement, we would add Cu-Be for the core top insert and cavity bottom in order to get best cooling effect. Compared to the steel material,Cu-Be material has fast cooling feature, which could reduce the cycle time about 3-5s per cycle.

Sino Holdings Group could offer one stop service for the milk crate production line, we make the milk crate mould, injection molding machine and other necessary additional machines to help the whole line running smoothly. If you need more information about the milk crate production plant set up, welcome to contact us. We are keen on whole production line service. Thanks.

Post by Miss Celina

Email: export07@sinogroupe.com

skype: sinomould.dakumar7

Whatsapp: 008615257606120