The battery plastic case made by ABS or PP, for different function. With Anti-fire ABS, the mould required with stainless steel to protect the mould well and hardness around HRC60. With precision tooling and mature mould assembling, the battery box mould could realize balance injection.

|

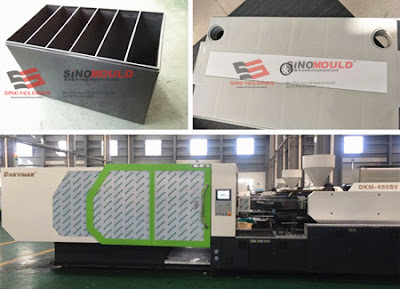

| Plastic battery box mould |

Mould name: 55Ah UPS battery box mould

Part dimension: 215*172*204mm

Part description:

Mould cavity no.: single cavity

Mould size: 750*600*710mm

Injection Machine: DKM450SV

Mould main steel material: S136

Mould life: 1M

Mould injection system: 7tips hot runner

system

Mould ejection system: Stripper plate

Battery box mould features: Advanced battery

box mould structure design, with optimized cooling system; Anole hot runner

system with 7tips injection; High precision tooling with QC report for each step.

Running cycle time: 45s

Delivery time: 65 working days

Sino Holdings Group manufacture plastic battery box mould and injection molding machines, We supply whole production line for new factory setup. If you are interested in the plastic injection molding industry, welcome to contact us. We offer not only the equipment, but also a fine solution.

Post by Miss Celina

Email: market1@dakumar.com

Whatsapp: 008615257606120

Thanks for sharing this blog, this blog is very helpful information for every one.

回复删除plastic molding company

plastic injection molded parts