Sino Holdings Group supply

high quality daily using production line with high production capacity and long running time. With our Dakumar injection molding machine manufacturing, we could supply high speed injection production line for daily using buckets, daily using chairs, tables and containers. Our engineer are professional for

mould making and injection molding machine operation, we could help customer set up new production line for different kinds of plastic products.

Our customer are ranging all over the world, we supply production line to South Africa, Tanzania, Algeria, Saudi Arabia, Turkey, Honduras, Brazil, Chile, Mexico, Iran and so on. According to customer requirement, we could design new products according to concept, with moldflow analyzing, the part strength and filling could check well before tooling.

|

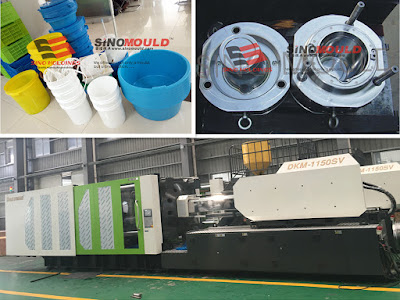

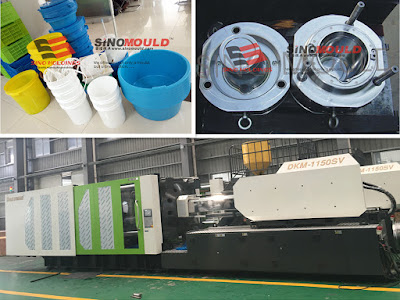

| Daily using bucket production line |

For the 80L bucket, we use P20 steel material with insolated gate to save the raw material wasting and invest cost, and it is smooth during filling without runner cutting after molding. If the bucket height could control within 560mm, we could use DKM1150 machine for the injection molding. We supply bucket mould,

bucket injection molding machine together with necessary additional machines.

For the customer who are new in the plastic injection molding industry, we could arrange our professional engineer to visit customer factory, help to design the workshop arrangement, assembling molding device, training staff and other technical support. Welcome to contact us if you need more information. Thanks.

Post by Miss Celina

Email: sinoauto@live.cn

Skype: sinomould.dakumar7

Whatsapp: 008615257606120