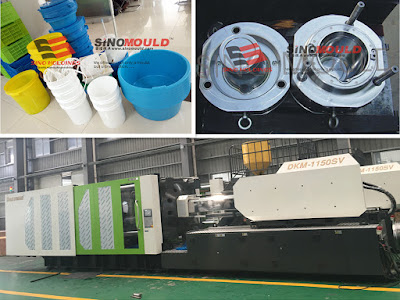

Sino Holdings Group make multi-cavity

solution for the PVC pipe fitting production line. We make PVC pipe fitting

mould, PVC pipe fitting injection molding machine and supply necessary

additional machines like autoloader, dryer, water chiller together with

technology support and service.

For the PVC raw material, consider the

feature of rusty to the steel material, we use stainless steel material for the

mould core and cavity, machine barrel and screw and other parts which touch

with the melting PVC material directly. For the mould base, normally we use

chrome painting to protect some accident if the temperature too high damage the

nearby plates. All the pipe fitting mould we designed with well cooling system

and precision tooling, the pipe fitting dimension could be well controlled.

We supply high quality PVC pipe fitting

injection molding machine, for the PVC injection molding machine, the main

difference compare to standard machine is the stainless steel for barrel and

screw, with cooling fans outside of the barrel, and the safety door is special

designed for the multi-direction moving of PVC pipe fitting moulds.

Post by Miss Celina

Email: export07@sino-mould.net

Skype: sinomould.dakumar7

Whatsapp: 008615257606120